Berson Rubber Interlocking Indoor Installation Manual

Ⅰ.PREPARATION

1. Subfloor Requirements

1) Hardness: No hollowing. No sand accumulation, sand loose, cracking while rubbing.

2) Flatness: Flatness should be measured with a 2-3 meter spirit level and a feeler gauge. It will be up to standard if the gap is below 2mm.

3) Cleanliness: Subfloors should be free of debris, paint, dust.

Note: Rough subfloors shall be constructed with extra strength self-leveling cement after they get cleaned up.

2. Accommodation to Job Site

Allow the material to sit in the area to be installed for a minimum of 24 hours to be acclimated at room temperature after packaging is opened on the job site. Do not store the material higher than 3packs. Lay down the tiles to the desired length and width. Inspect all materials for visual defects before beginning the installation. Position the tiles to avoid color variations caused by light angle.

3. Installation Requirements

1) Interlocking tiles should not be installed loose-laid in areas where are larger than 20M2.For areas where are larger than 20M2, adhesive must be applied to substrate.

2) Interlocking tiles should not be installed in areas where moisture content is high.

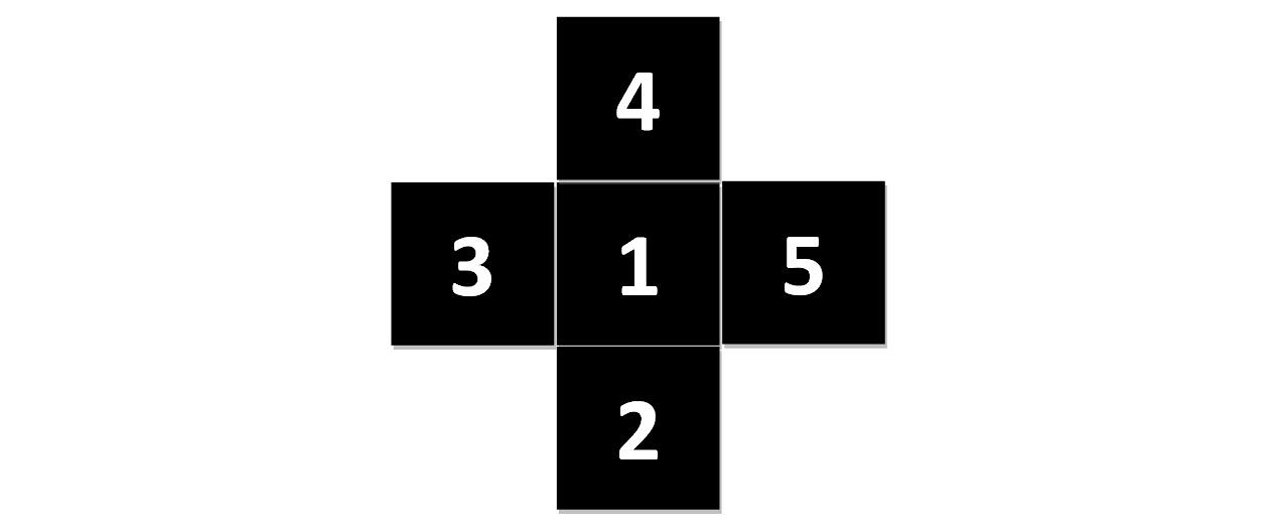

3) Installation layout: Begin the installations from the center of the room and work towards around, cross-shaped in clockwise direction. See diagram.

4) The gap between the tiles and the wall: Allow a 10MM around the perimeter for expansion and contraction of the tiles, fit against the wall with edgings.

5) All interlocking tiles must be installed in the same direction of arrow sprayed on the back.

Ⅱ.INSTALLATION

1. Adhesive Type

It’s recommended to use the two-component polyurethane adhesive. It’s mandatory to verify the type of adhesive before the application. (When the performance of the adhesive can not be identified, sample taken for adhesive bond tests should be conducted.)

2. Adhesive Mixing

Mix the adhesive evenly with the S shape mixer, in strict accordance with proportions as per the manufacturer’s instructions.

3. Adhesive Spreading

1) Precoating on subfloors for permeation treatment should be done before the adhesive is spread.

2) Spread the adhesive in the areaspre-coated, in accordance with the installation direction and position of the interlocking tiles.

3) Areas with adhesive spread must be 5CM bigger than the areas to be covered by the interlocking tiles. And full glue down is mandatory.

4) After the adhesive is spread, lay the interlocking tiles into the wet adhesive when viscosity works as per its properties.

4. Laying

1) Make sure the direction is same before the interlocking tiles are installed. Landscape and portrait orientation must be vertical.

2) The side joints between the tiles must be glued and interlocked tightly together in a single direction.

3) Tap the tabs in with a rubber mallet, and then press the tiles with a cork board to make them flat and tight.

4) Keep the tiles surface clean. Do not allow the adhesive to tarnish the tiles surface. If the adhesive drops on the surface by accident, care should be taken to NOT wipe off the wet adhesive with anything before it’s cured. Scrape the cured adhesive using a utility knife. Do not sand. Do not use any solvent. (Using solvents may cause distortion.)

Ⅲ.CLEANING & MAINTENANCE

1. Mop or wet vacuum floor daily. Regular cleaning is required for those high traffic areas.

2. Use neutral cleaning agents. Pick up solution with a wet vacuum.

3. Take care NOT to damage the floor with any sharp object. No cutting, no stabbing, no needling.

4. Take care NOT to pour any colored pigment or solvent on the floor.

5. Take care NOT to pour any oil, heat up,or light the fire on the floor.

6. It’s recommended to do the regular maintenance using transparent liquid wax to keep the surface bright.